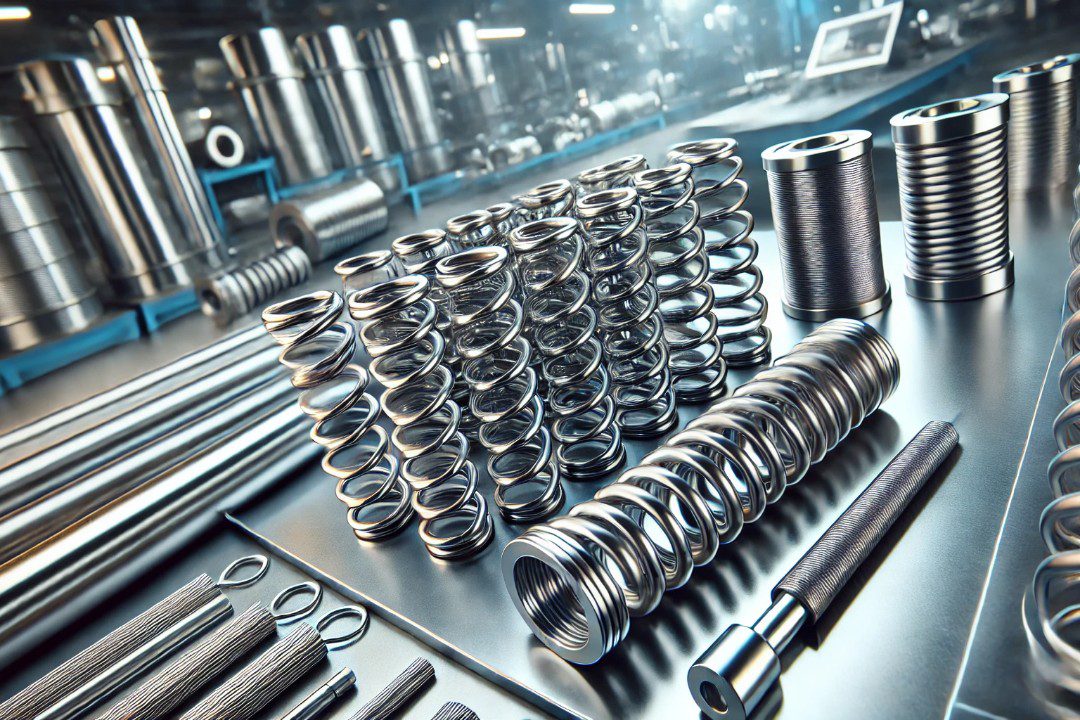

Alloy steel is a versatile and widely used material in spring and wire form manufacturing.

It combines iron, carbon, and various alloying elements, such as chromium, nickel, molybdenum, and vanadium, to achieve superior mechanical properties. Known for its strength, toughness, and wear resistance, alloy steel is ideal for high-performance applications in industries like automotive, aerospace, and industrial machinery.

At Western Spring Manufacturing, alloy steel springs and wire forms are crafted to meet demanding specifications, ensuring reliability and durability in challenging environments.

Alloy Steel Material Composition and Grades

Alloy Steel Material Composition

Alloy steel is composed primarily of:

- Iron: The base material.

- Carbon: Adds hardness and strength.

- Alloying Elements: Includes chromium, nickel, molybdenum, vanadium, silicon, and manganese to enhance specific properties, such as corrosion resistance, heat resistance, and toughness.

Common Grades of Alloy Steel

SAE 5160

- Composition: High carbon and chromium content.

- Properties: Excellent toughness and fatigue resistance.

- Applications: Automotive suspension springs, heavy-duty equipment.

ASTM A228 (Music Wire)

- Composition: High carbon with trace amounts of other elements.

- Properties: High tensile strength and elasticity.

- Applications: Compression and extension springs in industrial and consumer applications.

SAE 4140

- Composition: Chromium-molybdenum alloy steel.

- Properties: High tensile strength, excellent toughness, and wear resistance.

- Applications: Aerospace components, high-performance torsion springs.

SAE 6150

- Composition: Chromium-vanadium alloy steel.

- Properties: High yield strength and excellent resilience under stress.

- Applications: Automotive leaf springs, heavy machinery.

AISI 9260

- Composition: Silicon alloy steel.

- Properties: Superior resilience and resistance to deformation.

- Applications: High-performance coil springs, agricultural equipment.

Properties and Characteristics

Mechanical Properties

- High Strength: Alloy steel’s strength makes it ideal for heavy-duty and high-stress applications.

- Toughness: Withstands significant impact and stress without cracking or deforming.

- Fatigue Resistance: Performs well under repeated loading cycles, extending the lifespan of springs.

Physical Properties

- Wear Resistance: Stands up to abrasive environments, reducing maintenance needs.

- Corrosion Resistance: Enhanced with specific alloying elements, such as chromium or molybdenum.

- Temperature Tolerance: Maintains mechanical properties at high and low temperatures.

- Density: Approximately 7.85 g/cm³.

Spring and Wire Form Applications

Common Applications

- Compression Springs: Alloy steel compression springs are used in automotive suspensions, industrial presses, and heavy machinery.

- Torsion Springs: Provide durable torque in aerospace and defense systems.

- Wire Forms: Used in structural and load-bearing applications in construction and manufacturing.

Industries Using Alloy Steel Springs

- Automotive: Leaf springs, valve springs, and suspension components.

- Aerospace: High-strength springs in landing gear and flight control systems.

- Industrial Machinery: Heavy-duty springs in presses, stamping machines, and mining equipment.

- Agriculture: Springs in plows, harvesters, and other machinery subjected to intense stress.

Advantages and Limitations

Advantages

- Superior Strength and Durability: Ideal for applications requiring high load-bearing capacity.

- Wear Resistance: Performs well in abrasive and high-friction environments.

- Versatility: Alloy steel can be heat-treated to achieve a range of mechanical properties.

- Temperature Resistance: Suitable for extreme heat or cold applications.

Limitations

- Corrosion Susceptibility: Requires protective coatings or treatments for use in moist or corrosive environments.

- Machining Difficulty: High strength can make forming and machining more challenging, requiring specialized equipment.

- Cost: More expensive than plain carbon steel, though less costly than exotic alloys like Inconel.

Alloy Steel Compared with Other Materials

Alloy Steel vs. Carbon Steel

- Strength: Alloy steel offers significantly higher strength and toughness.

- Corrosion Resistance: Alloy steel, with added elements like chromium, outperforms carbon steel in corrosive environments.

Alloy Steel vs. Stainless Steel

- Cost: Alloy steel is more cost-effective but lacks the natural corrosion resistance of stainless steel.

- Applications: Alloy steel is preferred for high-stress applications, while stainless steel is chosen for environments requiring corrosion resistance.

Future Trends and Innovations

Advances in alloy design and heat treatment technologies are making alloy steel springs more versatile and cost-efficient. The development of nano-alloying techniques is further enhancing the material’s mechanical properties, enabling applications in extreme conditions.

Additionally, recyclable alloy steel is becoming more prominent, contributing to sustainable manufacturing practices in industries that prioritize environmental responsibility.